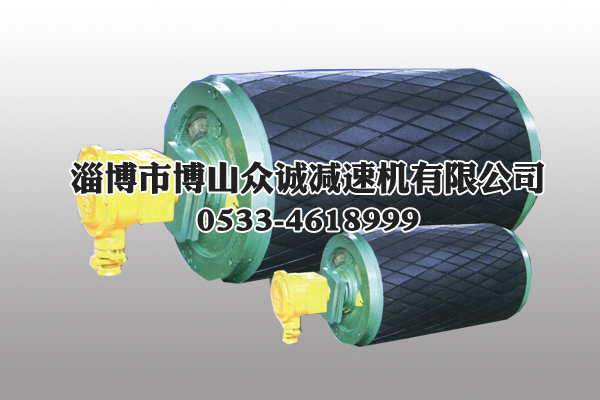

The product is used as the driving device of conveying machinery in the explosive mixture environment formed by combustible gas, gas, dust, etc. The products comply with the standard of 《the electric roller》JB/T7330-2008. The explosion-proof performance meets the requirements of 《Electrical equipment in explosive gas environment, general requirements》GS3836.1-2000, 《Electrical equipment for explosive gas environment, explosion-proof type "d"》GB3836.2-2000. The explosion-proof signs are dl、dIIAT4、dIIBT4. DI is applicable to the mines where there is methane or coal dust explosive dangerous mixtures, dIIAT4 is applicable to the places where there are T1~T4 explosive dangerous mixtures of class I and IIA, dIBT4, is applicable to the places where there are T1~T4 explosive dangerous mixtures of class I、IIA、IIB.

1. Overview: the explosion-proof electric roller is used as the driving device of conveying machinery in the explosive mixture environment formed by combustible gas, gas, dust, etc.

2. Working condition:

a) The ambient temperature is - 15 ℃ ~ 40 ℃;

b) Altitude not more than 1000M;

c) The temperature of conveying materials shall not exceed 60 ℃;

d) frequency:50Hz;

e) Voltage: 380/660V, 660/1140V。

3. Characteristic:

a) A flameproof enclosure that can contain all the electrical components that are easy to cause sparks;

b) Compact structure, small space;

c) Easy to use and maintain, safe and reliable operation, long service life

d) It can meet the requirements of various backstop, braking, rubber coating, etc

4. Basic parameter range of the product:

|

|

Dia.(mm)

|

Power(KW)

|

Strip width(mm)

|

Tape speed(m/s) |

Weight (kg) max. |

|

YDB-h |

400~500 |

3.0~22 |

650~1000 |

0.8~4.0 |

252~580 |

Dear Visitors, you are welcome to send enquiry to us for more details and proposal according to your special request.

Dear Visitors, you are welcome to send enquiry to us for more details and proposal according to your special request.